The Machine Shop is conveniently located in a separate building on the north side of the Texas A&M University Higher Education Center at McAllen. It is available to engineering students and faculty that require automatic and manual machines for projects.

Machine Shop Rules

- Each individual in the Machine Shop must wear safety glasses. Visitors will be provided with safety glasses at the entry door of the Machine Shop.

- Closed-toed shoes must be worn.

- Only certified workers can do walk-in work.

- Authorized workers are required to get shop supervisor approval before work is started.

- Workers are required to follow all standard shop rules and practices.

- Non-certified workers cannot work in the shop; they must have a certified worker perform all operations.

- Non-certified workers are allowed to observe or drop off work, but the supervisor must approve and be present while work is being performed.

- Individuals not working are not to be in the work area.

- The supervisor has the right to refuse any walk-in work.

- The individual for whom the work is being done is responsible for all damages. This individual is also responsible for the worker.

- Small jobs should not require more than 30 minutes of machine or bench time.

- Shop labor is free of charge for student and faculty projects. Material must be supplied.

- Work must not be dangerous to the equipment or the personnel.

Forms & Documentation

Read the Shop Manual.

Note: The Machine Shop Manual contains most shop forms and documents.

Procuring Materials & Raw Stock

Raw stock including but not limited to angles, bars, shapes, sheets, beams, channel, rods, plates, tubing, pipes, stainless, copper, brass, aluminum, galvanized and mild steel are required for projects in the Machine Shop.

Raw Material & Industrial Supply

Automatic Machines

-

This VF Series vertical machining center features a wide range of available options to customize a project to your exact needs.

- 3D models designed on Creo or Solidworks are to be saved in IGES or Step file format (ex: body parts, boat hull, wings, plane, etc).

- Codes for the machines can be written using Master Cam.

- 2D parts should be saved as IGES, wire frame, datum curves and points (in Creo shut off surfaces).

- Typical Tolerances: Average +/-.0005.

Travel:

X-Axis – 30 in (762mm)

Y-Axis – 16 in (406mm)

Z-Axis – 20in (508mm)

Learn more about the CNC Machine.

Read the manual.

View the Torque Chart.

Manual Machines

-

A high accuracy and easy to operate manual Coordinate Measuring Machine (CMM) featuring a frictionless air bearing suspension. It measures the geometry of physical objects by sensing discrete points on a surface of the object with a probe.

Learn more details about the CMM machine.

-

The Profile Projector is an optical measuring instrument that offers a high-tech touch screen M2 geometric measurement display. The measurement principle is similar to that of a microscope. This causes the targets profile, or shadow, to be shown on screen.

Learn more about the Profile Projector.

-

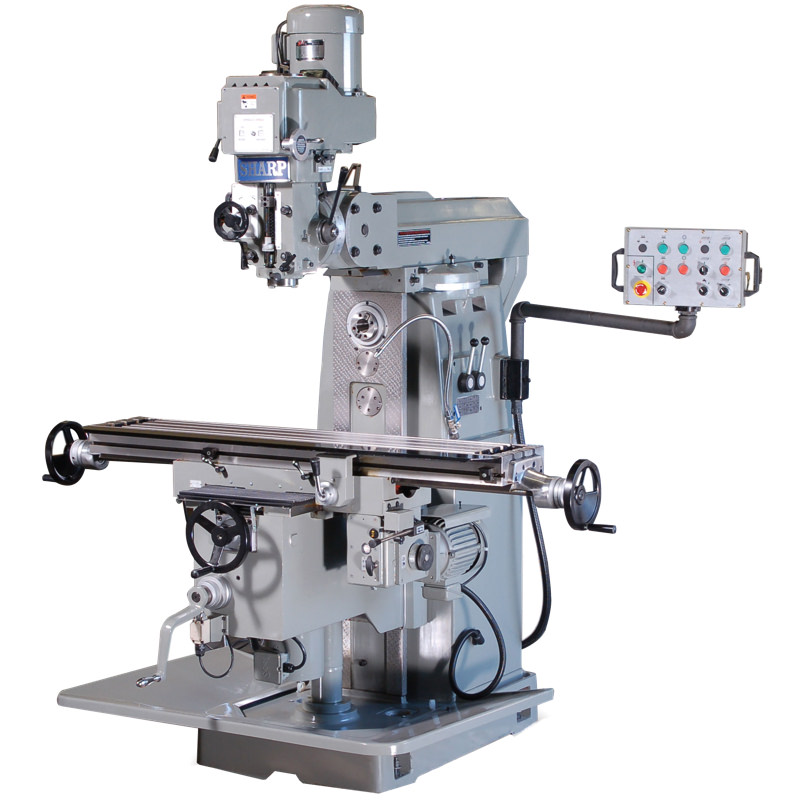

The Milling Machine removes material from a work piece by rotating a cutting tool and moving it through the piece. It can be used to drill, bore, cut and make threads and slots.

Learn more about the Milling Machine.

-

The Lathe Machine is similar to the milling machine, however, instead of cutting, you are shaping metal or wood with up to 16 speeds and you have the ability to use the convenient foot brake attached. It works by moving the workpiece around the stationary cutting tool and can be used for removing unwanted parts of the material.

Learn more about the Lathe Machine.

-

The Piranha P-50 Ironworker is a press brake used for bending sheet metal. It operates by clamping down the sheet or plate between moveable punch and by the stationary die.

Learn more details about this Press Brake.

-

The Sheet Cutting Machine is used for metal processing and industrial cutting, stamping, bending and forming sheet metal processing.

-

This Drill Press is used for metal processing and industrial cutting, stamping, bending and forming sheet metal processing.

Learn more about the Drill Press.

-

The Band Saw features a long sharp blade consisting of a continuous hand of toothed metal rotating on opposite wheels to cut materials or wood.

Read more about this Band Saw.

-

Depending on the bond and grade, this wheel grinder can be used for sharpening cutting tools such as tool bits, chisels and gouges. It can also be used to roughly shape metal prior to welding or fitting.

Learn more about the Surface Grinding Wheel.

Frequently Asked Questions

I was in the shop during my introductory course. Am I certified?

Introductory courses do not have very complex projects to prove proficiency and to be able to achieve full certification in the machine shop.

I found some material in the machine shop that worked for my project. Can I use it?

Often, if you find any material lying in the shop, it is somebody's project, therefore, do not use it without first asking and taking permission from the Machine Shop staff. Also, ask the staff where to store your project before leaving the shop.

Contact Us

Texas A&M University Higher Education Center at McAllen

6200 Tres Lagos Blvd

McAllen, Texas 78501

Machine Shop Phone: (956) 271-1365

Marie Amutan

- Technical Laboratory Coordinator

- Office: 316.15

- Phone: 956-271-1363

- Email: mamutan@tamu.edu

- Languages: English